Inside the 3 x 3 x 0.9mm LGA package are four separate metal oxide gas sensors, each with its own hot-plate, plus a processor whose algorithms decode the four sensor outputs into: ‘equivalent CO2‘ (400 – 65,000ppm), total volatile organic compounds (0 – 65ppm), AQI-U air quality index (scored 1 to 5, based on UBA (German environmental agency) index) and AQI-S air quality index (scored 0 to 500).

Raw sensor data is also available for external processing.

“Independent hotplate control allows the detection of a range of volatile organic

compounds including ethanol, toluene, hydrogen and oxidizing gases,” according to the company, which added: “It is highly immune to degradation caused by humidity or ozone.”

SPI and I2C interfaces are included for communication with a host processor.

Operation is over -40 to +85°C and 5 to 95% relative humidity.

Power is required at between 1.71 and 1.98V for the internal circuitry, and 1.71 to 3.6V to power the IO interface.

Battery operation is possible because the heaters can be time cycled – averaging 700µA in its once-per minute lowest power mode.

With precautions, the package is reflow solderable.

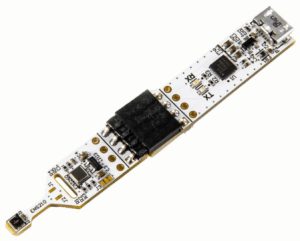

For development, there is an evaluation kit

Applications in wearables, domestic air sensors, ventilation systems, thermostats, cooker hoods and air purifiers are expected.

See ENS161 at the ScioSense stand (433 in hall 1) at Sensor+Test, which runs alongside the PCIM power exhibition in Nuremburg this week (9-11May).